Robotics Consulting, Process Development & Engineering

Project consulting for your robot-based automation project by our ArtiMinds Automation Engineering Team

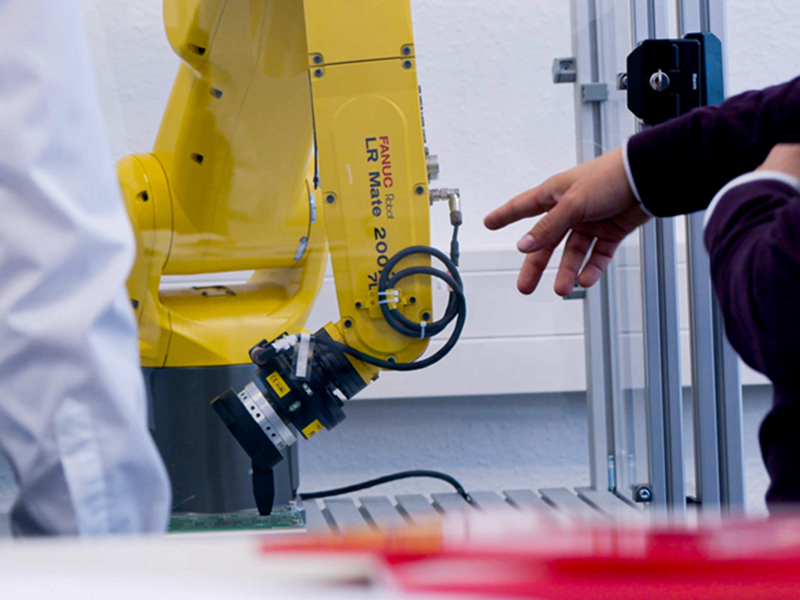

ArtiMinds is the perfect partner for your flexible robot-based automation solution and offers robotics consulting for any kind of application. Our application and robotics experts have tremendous experience in solving challenging automation tasks requiring force sensors, vision systems, complex tool paths or the integration of a master PLC.

The ArtiMinds experts of our Automation Engineering team will assist you in the planning of your automation project, the implementation of a prototype up to industrialization. For process development and validation we use our in-house software solutions (>>learn more).

In-depth training also ensures that you are able to create your individual flexible automation solutions independently on site.

CONCEPT DEVELOPMENT

- Idea development & consulting on feasibility

- Simulations with cycle time & reachability analyses

- Consulting in hardware selection

- Co-designing plant concepts

- and many more…

CONCEPT VALIDATION

- Robot feasibility/process studies

- Robot programming & configuration

- Performance tests in maximum tolerance range

- Detailed process data analysis & evaluation

- and many more…

Whitepaper: “Achieving Automation – But How?”

Which work tasks can be reasonably automated? How do you find the manufacturing processes with the greatest automation potential? What role does robot-based automation play? And what is the best approach during planning and implementation to avoid pitfalls?

The whitepaper provides you with helpful tips & tricks and guides you step by step from planning to implementation.

Robotics Consulting with Full Cost Control

We divide our project support into three phases. Thus, you have full cost control at all times and the possibility to terminate the project after each phase without further costs in case of lack of feasibility, unsatisfactory results or even if the automation project is not economically viable.

If required, we can draw on a wide network of partners to identify the perfect hardware for your project.

Phase 1: General feasibility study to evaluate the feasibility of your process

Here, the focus is on the general feasibility of the technological core of the task, e.g. the assembly of a flexible ob-ject, the assembly of tolerance-affected components or the development of a prototype.

Phase 2: Concept validation

If the project results of the feasibility study are positive, it will be possible to sharpen the requirements in more detail during concept validation by specifying certain framework parameters such as cycle time, feeding, reachability in existing production environments, speed etc.

Phase 3: Industrialization in cooperation with system integrator

In a third step, ArtiMinds supports the transfer of the developed prototype and the gained process know-how into a standard robot cell in cooperation with a system integrator or your internal special machine construction.

>>Factsheet

“Automation Engineering Services”:

Our Automation Engineering department has an extensive process know-how in YOUR application area:

Electronic & Mechanical Manufacturing

Manufacturing with Flexible Workpieces

Surface Processing

Customer voices about ArtiMinds and flexible automation with robots:

Benefit from our expertise for your first automation project:

Customer voices about ArtiMinds and flexible automation with robots

OUR ROBOTICS CONSULTING SERVICES

Planning phase

Let´s start with a “ROBOT-SUPPORTED AUTOMATION PROJECT”

Concept consultancy

ArtiMinds is a leading service and solution provider for demanding robot applications. Benefit from our many years of extensive experience in sensor-controlled robotics with our robotics consulting. We develop innovative concepts and solutions for your idea for automation with robots. A customized, innovative and efficient concept from ArtiMinds considers aspects such as feasibility, technical implementation, benefits, effort and much more. By using our robot software ArtiMinds RPS and LAR, we also reduce the need for purpose machinery to a minimum.

Considering state-of-the-art technology, our concept consultancy will reduce the time to launch your challenging automation solution significantly.

Identification of key challenges

Each task has its own particular challenges, which are identified and narrowed down by our specialists. This minimizes risks right from the start and significantly shortens the time required for feasibility studies for new approaches.

Talk to us and benefit of ArtiMinds’ industry-leading expertise.

Implementation phase

From a feasibility study to the implementation of a prototype

Feasibility studies

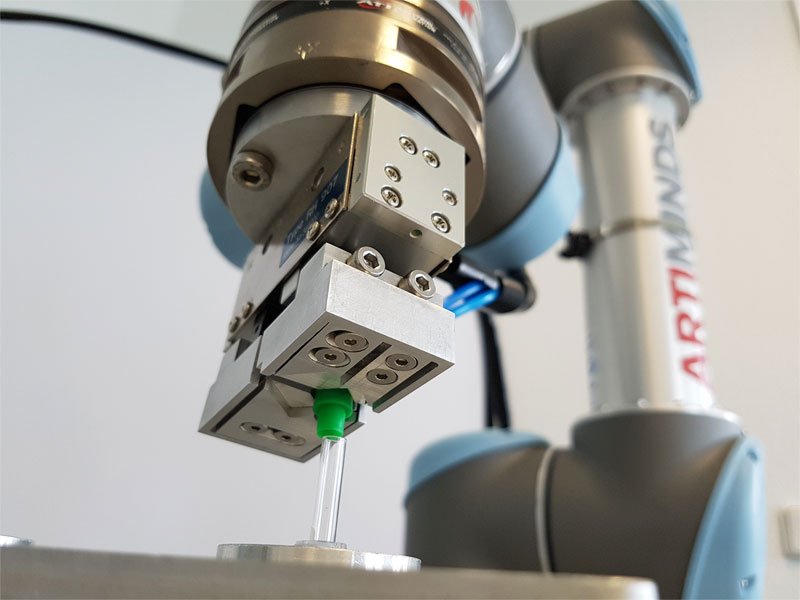

Feasibility studies are used to investigate and evaluate key challenges and concepts. ArtiMinds cooperates with all well-known robot manufacturers and has a wide range of robots and peripherals in-house, which i.a. has a positive effect on the time required. Feasibility studies build the foundation to dive into new areas of flexible automation solutions. Finally, we will provide you with comprehensive documentation containing detailed insights into the examined process based on ArtiMinds LAR.

Realization of technology prototypes

ArtiMinds fully supports you in the realization of prototypes of your automation solution. Highly sophisticated technical challenges, where no turnkey solution is available on the market, will be addressed and realized. The ArtiMinds solution for your automation project will convince you: The result will be an outstanding technology flagship that can lead to a significant competitive advantage.

Knowledge transfer

Create your own robot-supported automation processes with ArtiMinds RPS

Transfer of process know-how

The standardization of workflows leads to more effectiveness and efficiency. And this is exactly what is possible with the ArtiMinds software family, easily and consistently. One of the main benefits is the management, refinement and reusability of your process know-how leading to a significant competitive advantage.

The implementation of these functionalities is an expression of our conviction that know-how is not an island. At ArtiMinds robotics consulting and a project is only considered complete after a comprehensive knowledge transfer, which marks the end of every project. We want you to act as a specialist for your robot-supported processes and, building on this, successively expand or deepen your knowledge.

Strategically organize and refine process know-how

In business life, but especially in industrial manufacturing, standing still is not a desirable state. In terms of optimizing existing processes and developing new ones, the strategic organization of process know-how is of great relevance. Here, you can count on the expertise of ArtiMinds as well as for further refinement. For us it is important to identify potentials that have not been used so far and to define a clear structure together with you.

At ArtiMinds your project is in good hands. Contact us and let us find the optimal flexible automation solution for you.

LET´S GET IN TOUCH & GET FREE ADVICE

Our experts will be happy to support you

ArtiMinds for your robotic automation project!

You want to integrate new and flexible robot-supported automation processes into your workflows?

ArtiMinds is a leader in the development of innovative and complex robotic automation solutions, whether as a partial or overall concept.

Our experts are happy to provide you with advice and support from conceptual design to implementation. Get in touch, our specialists will provide you with comprehensive advice and work with you on an initial concept or feasibility studies.

Write to us and start your automation project with ArtiMinds.

Online and offline programming:

With ArtiMinds RPS you can plan, program and implement all robot-supported automation processes consistently and seamlessly in online and offline mode. Use the simulation environment to program your robot offline or teach your industrial robot online, and let the software write the manufacturer’s specific robot code in the background. Save expensive resources, cash and valuable time with ArtiMinds RPS.