Efficient programming and teaching of KUKA robots

ArtiMinds – The software for KUKA.WorkVisual compatible robot programs

Standard programming of KUKA robots is done by writing KUKA Robot Language (KRL) code in the system software KUKA.WorkVisual or KUKA Sunrise.OS. Despite that KUKA.Sim specifically supports the simulation of KRL programs and offline programming.

When it comes to programming and teaching KUKA robots, the software ArtiMinds RPS is a real alternative, as all functions are available in only one software and no script code has to be written. Even demanding robot applications can be easily programmed with ArtiMinds without having to write a single line of native KUKA program code yourself.

KUKA currently offers around 25 industrial robots in numerous variants with a wide variety of payloads and ranges. KUKA robots are therefore suitable for almost all applications. In the areas of handling, assembly, palletizing and packaging, KUKA’s industrial robots have a great impact.

However, the numerous application possibilities and features also quickly make programming complex, and users often lack the programming skills, to take full advantage of all the functions and being able to use them for their application.

The robot programming software ArtiMinds RPS supports all KUKA 6-axis robots with KR C4 and KR C5 (with KSS 8.7) controller.

KUKA Robot Programming in Practice

Why programming KUKA robots with ArtiMinds?

You would like to solve demanding tasks with your KUKA robot without having to put days of effort into programming? You are planning your first robot-supported automation project and would like to use a KUKA robot? You would like to remain manufacturer-independent and be able to transfer applications to other robots without reprogramming?

With ArtiMinds software solutions you and your employees are able to realize any kind of application and to program and teach your robot yourself – without the need for lengthy and expensive KUKA training. Thanks to more than 60 predefined motion templates, ArtiMinds ensures robust industrial applications and faster programming. That means less costs, more efficiency and new application possibilities for you.

ArtiMinds & KUKA – Your Takeaways

- Native reusable KRL code is automatically generated

- Use the full functionality of the KUKA robot without special programming knowledge

- ArtiMinds RPS as an alternative to KUKA.WorkVisual, KUKA.Sim or various application software from KUKA

- A software solution for online and offline programming, simulation and optimization

Choose a robust, flexible and affordable automation solution – choose ArtiMinds.

We would be happy to show you the range of applications and how to program KUKA robots with ArtiMinds in an online demo.

How does ArtiMinds support the efficiency of your KUKA robot?

To get the most out of your KUKA robot, ArtiMinds offers two approaches – ArtiMinds Robot Programming Suite (RPS) and ArtiMinds Learning & Analytics for Robots (LAR).

ArtiMinds Robot Programming Suite (RPS) combines as robot programming software both online and offline programming in an intuitive way to solve challenging robotic tasks of your KUKA robot without writing a single line of KRL source code. Integrate end effectors, force torque sensors, vision systems and PLC communication to create flexible automation solutions.

The automatically generated robot code runs directly on the KUKA KR C4 or KR C5 robot controller – ArtiMinds RPS requires no additional hardware.

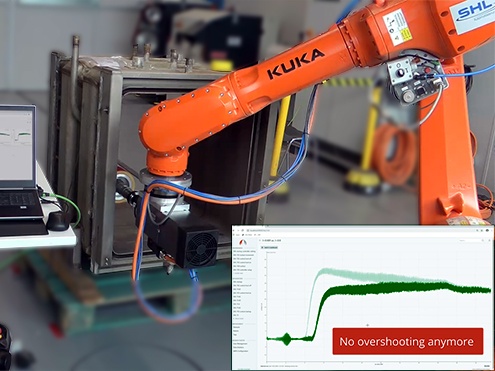

With ArtiMinds Learning & Analytics for Robots (LAR) you get detailed insights into the production processes of your KUKA robot. Based on ArtiMinds RPS, live sensor data from the robot, force sensor, vision system and end effector are automatically transferred from the KR C4 and KR C5 robot controller. The sensor data is automatically annotated and permanently stored in your internal database. Analyze this sensor data using various KPIs and graphical evaluations. In this way, you are able to easily monitor production, analyze robot movements and optimize your KUKA programs.

What we can do to make KUKA robots more efficient

With ArtiMinds RPS and LAR we facilitate the development and operation of flexible automation solutions with KUKA robots and many other robot types in almost all industries. Below you will find some application examples for programming KUKA robots with ArtiMinds. However, our solutions also help with the automation of processes in other areas.

KUKA ROBOT PROGRAMMING – GET STARTED AND LEARN MORE IN A FREE ONLINE DEMO

In just a few minutes, we will show you how to plan, program, operate, analyze and optimize KUKA robot applications cost-efficiently, intuitively and easily with ArtiMinds RPS.The non-binding free online demo is the perfect way to get a first impression of the software, the application portfolio and if it suits your needs.