Robot-based mechanical assembly

Automate demanding assembly applications economically and profitably

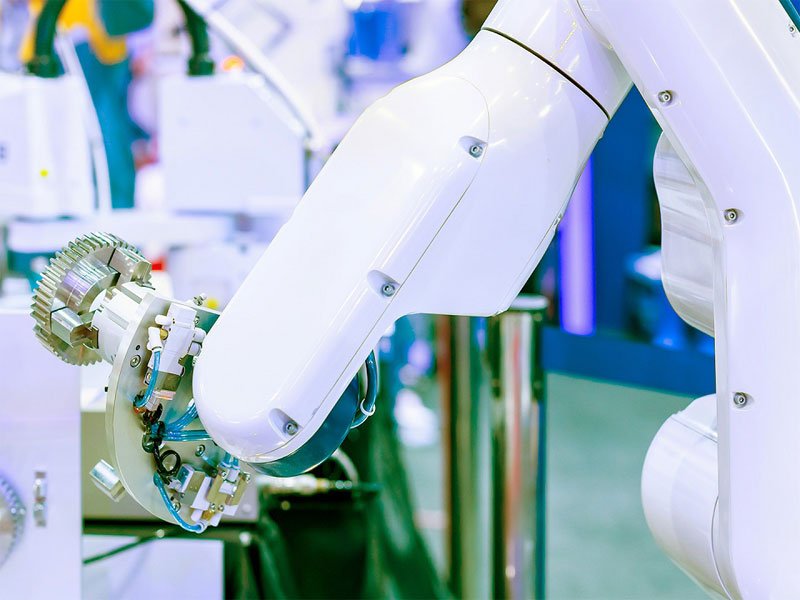

The software ArtiMinds RPS enables the automation of complex assembly applications in a wide range of industries and manufacturing processes. Parts made of rigid as well as flexible materials can be inserted, joined, clipped, riveted, glued or screwed together using using force-sensitive robot motions. Even challenging applications become economically feasible due to the easy integration of force sensors and automatic robot code generation allowing to quickly test different assembly strategies.

Different product variants, small batch sizes and short product life cycles often make the robot-based automation of assembly tasks unprofitable for companies. In addition, these are usually very complex and error-prone processes that can be solved more safely and quickly with human fine motor skills.

You need support in automating an electronics assembly process? At ArtiMinds you get software & project support from a single source!

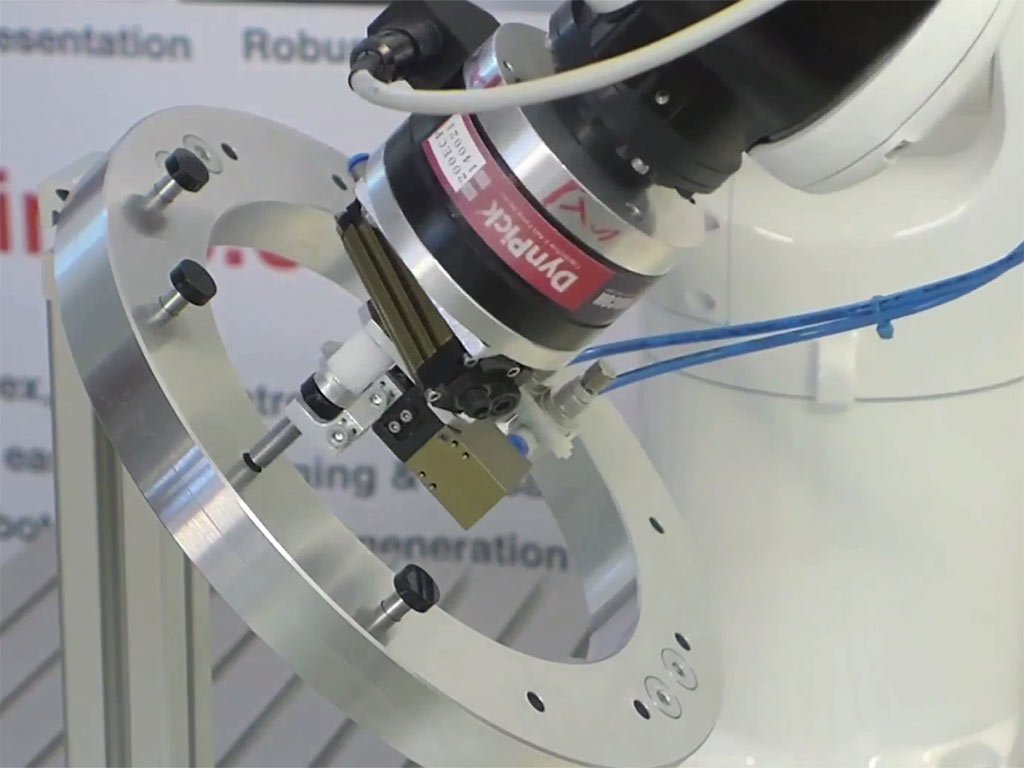

Application example: Precise assembly of various components

For assembly processes it is often necessary to handle several components with one robot. To assemble a cylinder head for example, the fitting sleeves and the seal must first be inserted before the cylinder head is mounted. This shows that in most cases, the components also differ in material and geometry. Therefore complex gripper geometries are required. In the ArtiMinds RPS an automation with a multiple-TCP gripper solution is easy to implement.

The components have a high fitting accuracy and require a lot of sensitivity during assembly. Using the search algorithms of ArtiMinds RPS, the exact fitting position can be found first and afterwards the components can be inserted while compensating the lateral forces and moments.

ArtiMinds RPS is therefore the first choice when it comes to solving the most demanding assembly processes using industrial robots. With the help of sensor-adaptive templates, the robot software is able to execute force-sensitive processes such as clipping, screwing, riveting and plugging time-optimized and robustly or, for example, to even adapt the screwing speed. In the case of unsorted parts, a camera system can be easily integrated to localize and reliably grip the pieces. As the interfaces are already implemented in ArtiMinds a simple and effortless hardware integration is ensured.

Further application examples:

- Joining parts with tight tolerances

- Placement of plastic clips, seals, plugs or rivets

- Gearbox and engine block mounting

- Placing and fastening of screws

- Realization of gluing applications

You want more? We support you in the robot-based automation of your mechanical assembly processes

You want more? We support you in the robot-based automation of your mechanical assembly processes

You want to integrate new and flexible automation processes into your workflows and need e.g. support in the automation of clipping, screwing, riveting and plugging of workpieces? Our Automation Engineering team of engineers and robotics experts will be happy to advise you and take over tasks such as the prototyping.

ArtiMinds is a leader in the development of innovative and sophisticated robot automation solutions, whether as a partial or overall concept. Our experts will be happy to provide you with advice and support from conceptual design to implementation.

Get in touch – our specialists will provide you with comprehensive advice and develop an initial concept or carry out a feasibility study in close cooperation with you.

Industrial examples – short videos of real customer applications

ARTIMINDS – YOUR HOLISTIC ROBOTICS PARTNER FOR MECHANICAL ASSEMBLY

OUR OFFERING:

Link to: Robot Programming Software

ROBOTICS SOFTWARE

Link to: Consulting & Engineering

ROBOTICS ENGINEERING

Why ArtiMinds Robotics?

ArtiMinds RPS meets the high requirements of mechanical assembly because of its sensor-adaptive and intelligent program templates . Its hardware independence allows you to remain flexible and save time, costs and human resources thanks to its simplified, intuitive and nevertheless robust robot programming.

>>READ THIS BLOG POST: ArtiMinds RPS & LAR at a glance

Highlights of ArtiMinds RPS for mechanical assembly:

- Highly customizable assembly strategies

- Fast solution finding

- Suitable for rigid and flexible materials

As an innovative solution and service provider in the field of robotics, ArtiMinds offers outstanding support when it comes to implementing your automation solution. Get to know ArtiMinds in a free online demo!

>>THAT´S WHAT OUR CUSTOMERS SAY<<

Just get in touch. Our application experts will be happy to advise you on your individual automated robot application. Make an appointment right now for an online demo and learn how ArtiMinds can help you to implement a flexible robotic automation project.

Browse through our Robotics Blog or FAQ section and learn interesting facts about ArtiMinds RPS & LAR. Our Download & Press area provides further information. Or sign up to our newsletter for regular news and ongoing updates.

FREE ONLINE DEMO: GET STARTED AND LEARN MORE ABOUT ROBOT-BASED AUTOMATION

In just a few minutes, we will show you how to plan, program, operate, analyze and optimize robot applications cost-efficiently, intuitively and easily with ArtiMinds RPS.

The non-binding free online demo is the perfect way to get a first impression of the software, the application portfolio and if it suits your needs.