Handling and packaging by strong robot arms

Program robots robustly for handling & packaging tasks

Solve all your handling and packaging applications with a single software. Our versatile programming templates enable your robot to handle flexible materials, such as cardboards, identify and localize parts using vision systems or pick up parts from stacks, blisters or any kind of work piece carriers.

Optimize your goods handling with the software ArtiMinds RPS. Using special program modules, your robot can handle flexible materials such as cardboard or cardboard boxes, align itself visually or pick up goods from stacks, blisters or any work piece carriers and boxes (bin picking).

In logistics applications in particular, there are often process variations and product tolerances, which have to be compensated by the robot (i.e. palletizing tasks) With the predefined templates of ArtiMinds RPS, such force-adaptive robot movements can be robustly programmed without having to write a single line of robot code yourself. In this way, tasks such as tight palletizing can be easily automated with robots. If you would like to integrate vision systems to detect objects, the vision templates simplify programming.

You need support in automating an electronics assembly process? At ArtiMinds you get software & project support from a single source!

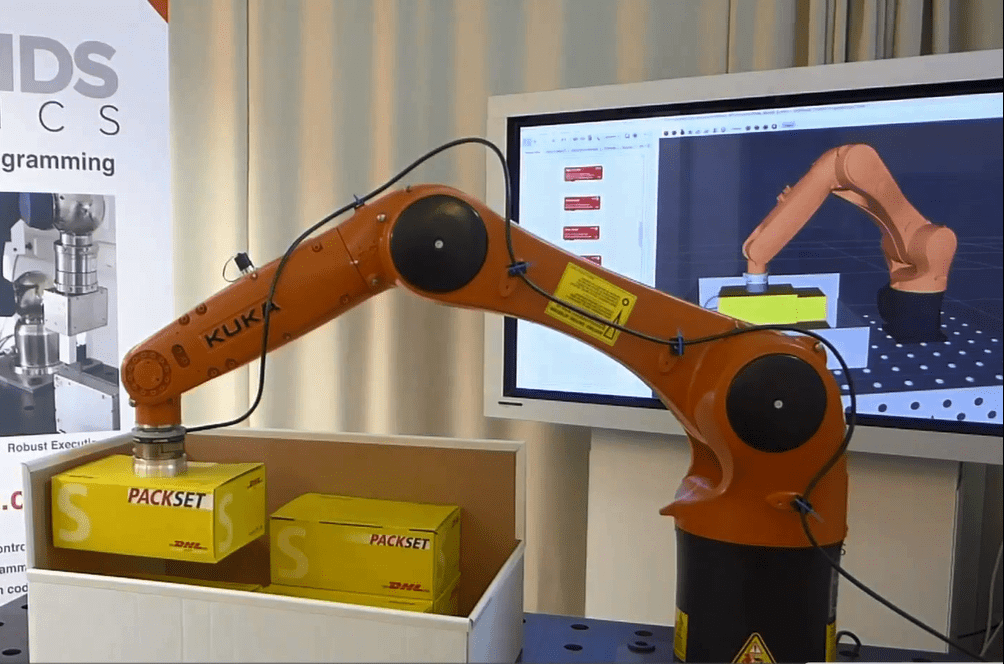

Application example: Palletizing of cardboard boxes

Palletizing is a common task in logistics and material supply. In most cases, the parts that have to be palletized are unsorted without a defined position, e.g. in lattice boxes. This makes it difficult to automate such Pick & Place tasks.

With ArtiMinds +Vision the position of an object can be captured by a camera. Thanks to the integrated interfaces, ArtiMinds RPS processes this data automatically so that the robot can grip the cardboard correctly and precisely.

If the cardboards are transported on a conveyor belt, for example, the robot must wait for the corresponding PLC signal before the gripping process. Since ArtiMinds RPS supports various communication protocols, this application can also be easily solved with the software.

Further application examples:

- Machine loading

- Force-controlled stacking

- Tight palletizing

- Unfolding of packaging material

- Bin Picking

You want more? We support you in the robot-based automation of your bin picking application

You want more? We support you in the robot-based automation of your bin picking application

You want to integrate new and flexible automation processes into your workflows and need e.g. support in the palletizing of cardboard boxes or gripping of unsorted workpieces? Our Automation Engineering team of engineers and robotics experts will be happy to advise you and take over tasks such as the prototyping.

ArtiMinds is a leader in the development of innovative and sophisticated robot automation solutions, whether as a partial or overall concept. Our experts will be happy to provide you with advice and support from conceptual design to implementation.

Get in touch – our specialists will provide you with comprehensive advice and develop an initial concept or carry out a feasibility study in close cooperation with you.

Industrial examples – short videos of real customer applications

ARTIMINDS – YOUR HOLISTIC ROBOTICS PARTNER FOR HANDLING & PACKAGING

OUR OFFERING:

Link to: Robot Programming Software

ROBOTICS SOFTWARE

Link to: Consulting & Engineering

ROBOTICS ENGINEERING

Why ArtiMinds Robotics?

Even in applications with cobots, which are inherently easier to program, the program logic can quickly become complex as soon as sensors are integrated. Save time, money and human resources with ArtiMinds RPS by also being able to implement sensor-based robot applications independently, e.g. to automate the manual loading of machines.

>>READ THIS CASE STORY OF MANN+HUMMEL: Robot takes over machine loading

Highlights of ArtiMinds RPS for handling & packaging:

- Custom pick & place patterns

- Easy integration of vision systems

- Suitable for rigid and flexible materials

Decide for a robust, flexible and affordable automation solution – choose ArtiMinds. We would be happy to show you the possibilities in a short online demo!

>>THAT´S WHAT OUR CUSTOMERS SAY<<

Link to: Referenzen

Despite very flexible and different product variants and quantities, Mann+Hummel managed to implement a cost-efficient automation solution for their 2D Bin Picking application with ArtiMinds RPS.

Just get in touch. Our application experts will be happy to advise you on your individual automated robot application. Make an appointment right now for an online demo and learn how ArtiMinds can help you to implement a flexible robotic automation project.

Browse through our Robotics Blog or FAQ section and learn interesting facts about ArtiMinds RPS & LAR. Our Download & Press area provides further information. Or sign up to our newsletter for regular news and ongoing updates.

FREE ONLINE DEMO: GET STARTED AND LEARN MORE ABOUT ROBOT-BASED AUTOMATION

In just a few minutes, we will show you how to plan, program, operate, analyze and optimize robot applications cost-efficiently, intuitively and easily with ArtiMinds RPS.

The non-binding free online demo is the perfect way to get a first impression of the software, the application portfolio and if it suits your needs.