Complex robot applications simply implemented

acp systems AG

Innovative solution for demanding automation tasks

CHALLENGE

Whether it’s complex cleaning operations with the dry quattroClean snow-jet technology, the application of flexible foils and substrates to curved surfaces, or the high-precision grinding and polishing of free-form surfaces – these are just a few of the typical tasks that robots are capable of performing efficiently, reliably and reproducibly. Despite this, manufacturing companies with low to mid-sized product volumes, an extensive or frequently changing range of parts, or which process complex components, are often particularly reluctant to implement robots. The reason for this is not the hardware – a wide variety of robots are now available at comparatively low cost.

The stumbling block is planning, compiling and maintaining the robot programs. Up till now, this involved a great deal of effort as well as manufacturer-dependent programming specialists, which also cost a lot of money. Programming complex motion sequences for sensor- based applications is a particular challenge.

APPLICATION

WHY ARTIMINDS?

Up till now, numerous costly programming hours, extensive test runs, and adjustments were required to precisely adapt the motion path to the shape of strongly structured components or curved surfaces. The fact that CAD data for path generation and sensory components can be integrated with ArtiMinds RPS significantly simplifies and shortens robot programming for such complex applications. In addition, any necessary changes can be made quickly and efficiently in-house by acp systems.

SOLUTION

Solve complex automation tasks easily

The following example illustrates the resulting advantages. During the automated quattroClean process to clean strongly-structured components with free-form surfaces, undercuts, and integrated pipes, the robot must be capable of precisely traversing complex path curves and geometries. Using conventional techniques to program and align these motion sequences is extremely difficult and time-consuming and requires a great deal of expert knowledge.

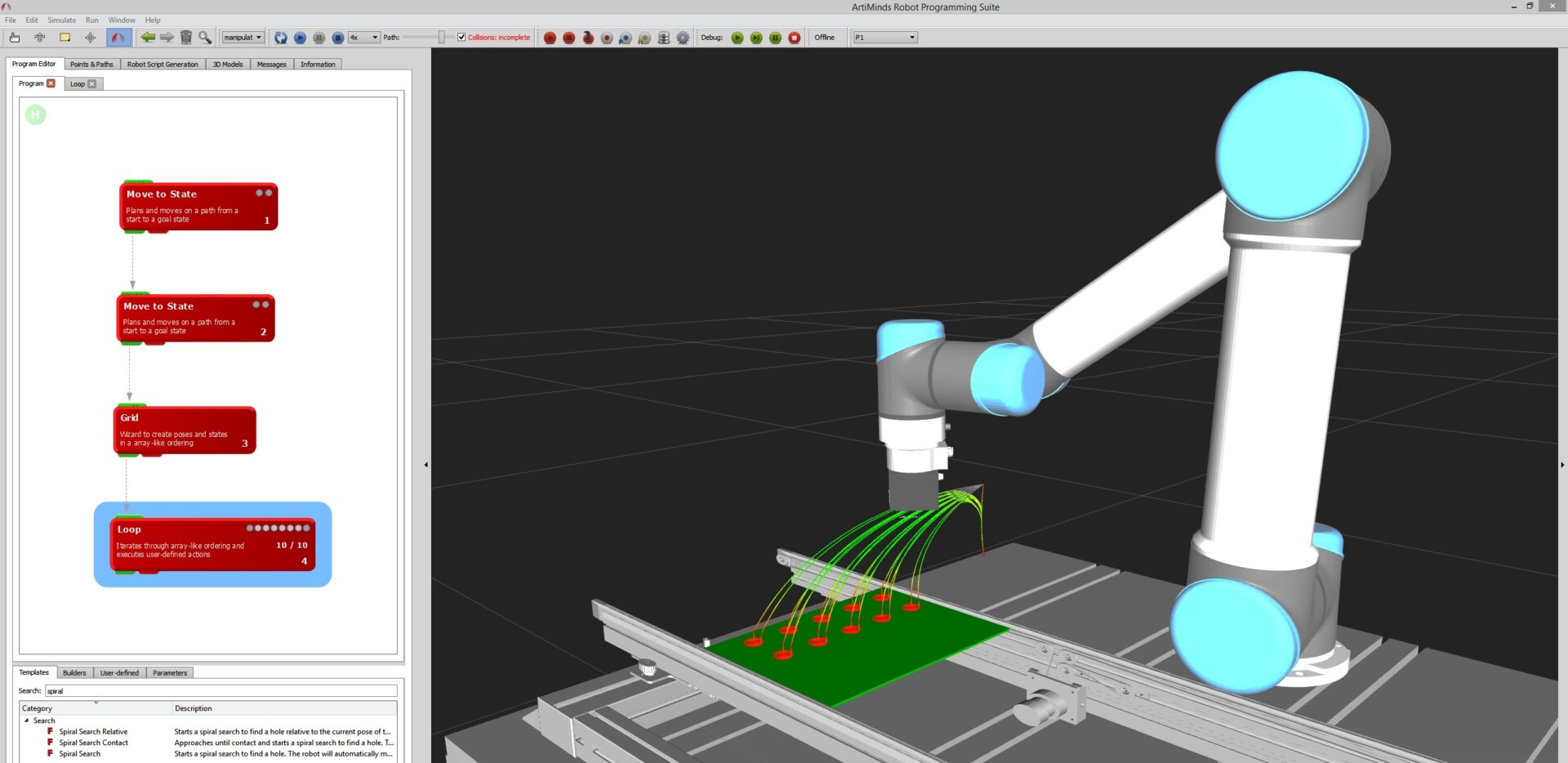

In contrast, CAD parts data can be easily imported into the 3D simulation environment and offline programming with the ArtiMinds RPS software tool, which then generates the necessary motion paths automatically. The sequence of the various processes, i.e. the movements and work steps that the robot has to perform during cleaning, is generated by dragging and dropping pre- programmed function modules. The robot’s teach-in mode can then be used to align the sequence to the part and thus test the program. In the last step, the generated program is automatically translated into the robot’s target language. Supplemented by process- and task-specific parameters, such as jet time, pressure and volume flows for carbon dioxide and compressed air, as well as the number of jet nozzles, the application can be effectively automated with robots in a comparatively short time.

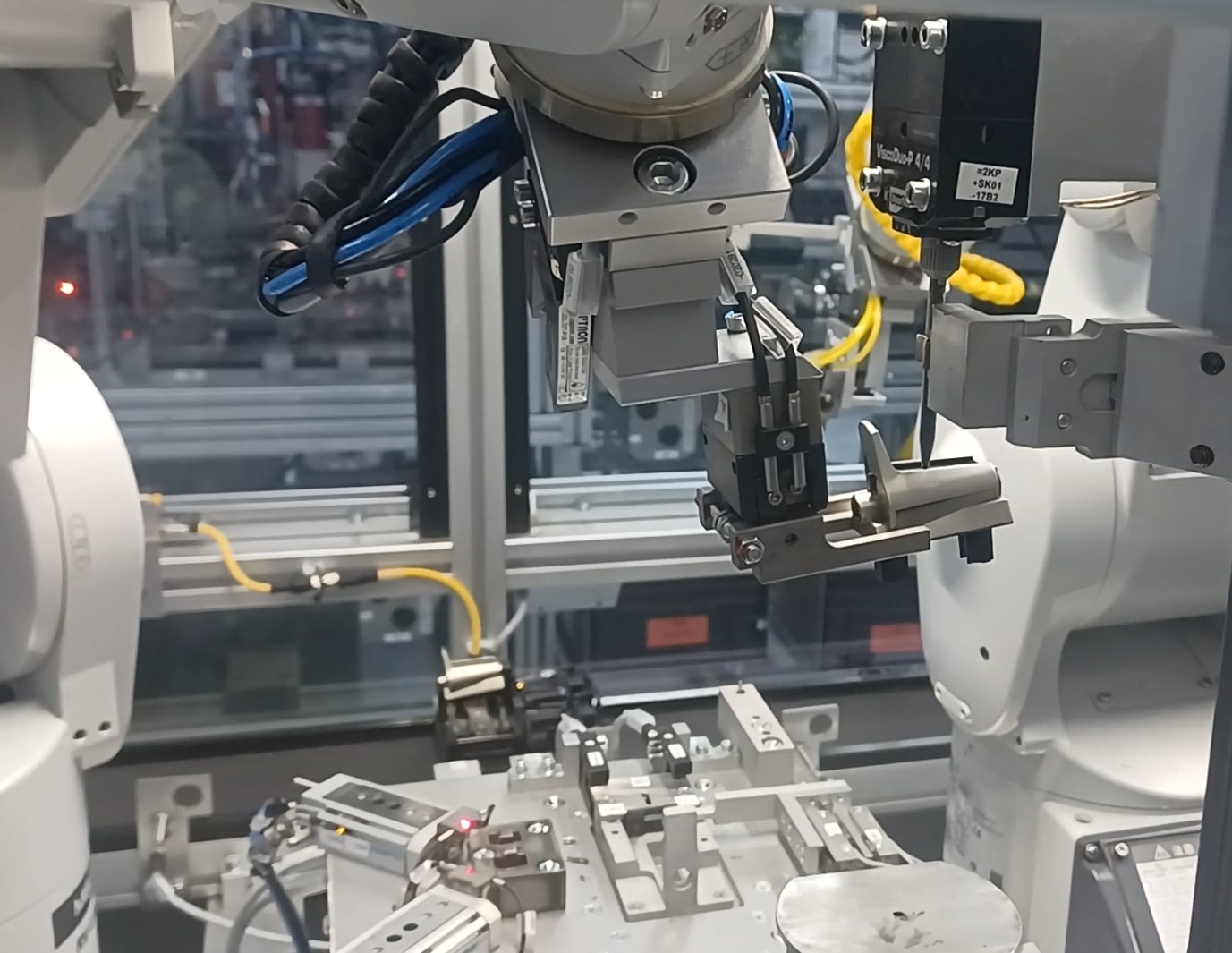

When applying foils and substrates, including touch foils and flexible PCB’s to curved surfaces, it is essential to avoid air pockets or particulate contamination. In addition, the robot has to peel off the protective layer without damaging the foil underneath. To ensure this, the robot has a gripper modelled on the human hand that holds the foil as a roll and applies it to the surface without entrapping any air. This task is also one of the applications that places high demands on robot programming when it comes to automation. Up till now, numerous costly programming hours, extensive test runs, and adjustments were required to precisely adapt the motion path to the respective free-form surface. The fact that CAD data for path generation and sensory components can be integrated promises to significantly simplify and shorten robot programming for these applications as well. In addition, any necessary changes can be made quickly and efficiently in-house.

„From complex dry-cleaning applications to the application of flexible foils to curved surfaces to high-precision grinding and polishing of free-form surfaces, the ArtiMinds RPS software solution enables easy programming of robots including the compatible peripheral hardware such as grippers, cameras, force-torque sensors, without you having to write a single line of code yourself.“

acp systems AG

Take Aways from acp systems when using ArtiMinds RPS:

- Offline and online programming are seamlessly combined, enabling programs to be efficiently generated and consistently planned, programmed and put into operation.

- The graphical, intuitive user interface and pre-programmed function blocks make it possible to solve complex automation tasks even with little or no programming knowledge.

- Offline programming: Using CAD data, paths can be generated automatically and thus robot programs can be adapted quickly and cost-effectively to different component geometries.

- Path planning for complex geometries and integration of sensory components without having to write a single line of robot code.

GET STARTED AND LEARN MORE IN A FREE ONLINE DEMO

In just a few minutes, we will show you how to plan, program, operate, analyze and optimize robot applications cost-efficiently, intuitively and easily with ArtiMinds RPS.

The non-binding free online demo is the perfect way to get a first impression of the software, the application portfolio and if it suits your needs.

In our robotics blog you will find the latest news and topics from industry and ArtiMinds.

Learn more!

Link to: ZF Friedrichshafen

Program and simulate robot applications independent of manufacturers, reduce maintenance costs and alleviate the lack of skilled workforces. Find out how ZF succeeds thanks to ArtiMinds!

MUCH MORE THAN JUST SIMPLE ROBOT PROGRAMMING: With RPS you create cross-process standardization – from planning and programming to maintenance.