ROBOTICS NEWS

Robot-supported ultrasonic defect testing and quality control

Ultrasonic testing is a widely used non-destructive test method to check cast parts for invisible defects such as blowholes, pores or cracks. Since the acoustic properties of the material change if those casting defects are present, the ultrasonic sound pulse is reflected and sent back to the test head.

Especially if components have complex geometries, ultrasonic testing is often carried out manually. By automating the process with the help of robots, test costs and test time can be reduced and measurements made reproducible.

Force controlled movements

For a successful test, a constant contact pressure of the test head is important. This can be ensured by using a force-torque sensor. In this way, the robot can move force controlled along the trajectory of e.g. a wheel rim to detect non visible defects with the ultrasound test. All sensor data and test results are automatically and completely documented.

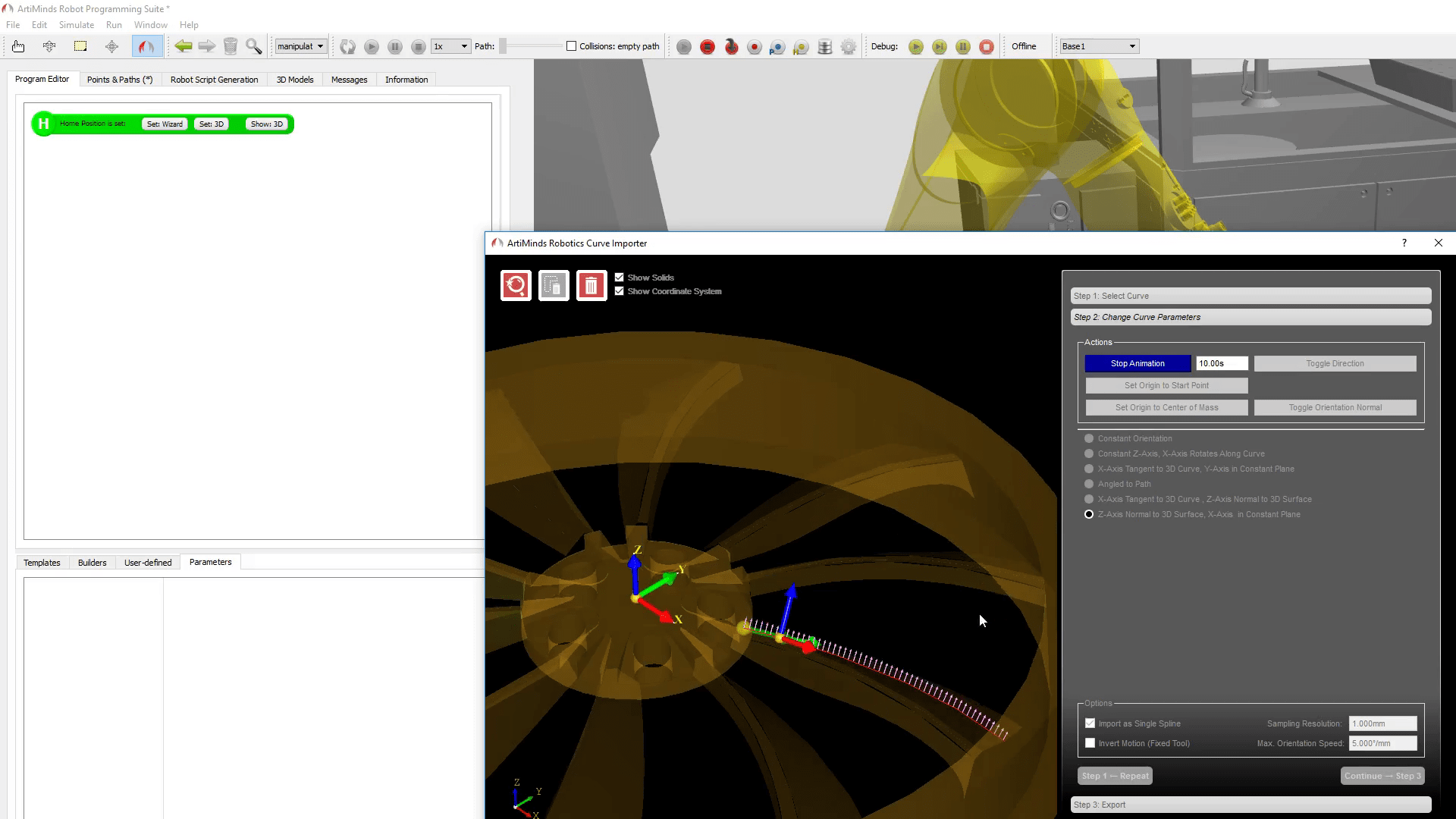

Minimal programming effort even for complex geometries

Software solutions such as ArtiMinds RPS minimize the programming effort occurring for complex component geometries. The robot movement or path is generated automatically based on the CAD object of the component, which can be imported with one click. This simplifies programming and eliminates the need for manual teaching of complex trajectories. In addition, special, predefined program templates support the force controlled movement of the component, so that the alignment of the test head on curved surfaces is carried out automatically without the need to integrate a camera.

How did VISOMAX solve the polishing of painted surfaces with robots? Find out more!

We answer the most important questions about the ArtiMinds software solutions, applications and the company in our FAQ section.

MUCH MORE THAN JUST SIMPLE ROBOT PROGRAMMING: With RPS you create cross-process standardization – from planning and programming to maintenance.