INDUSTRY NEWS

Overcoming the challenges of THT assembly

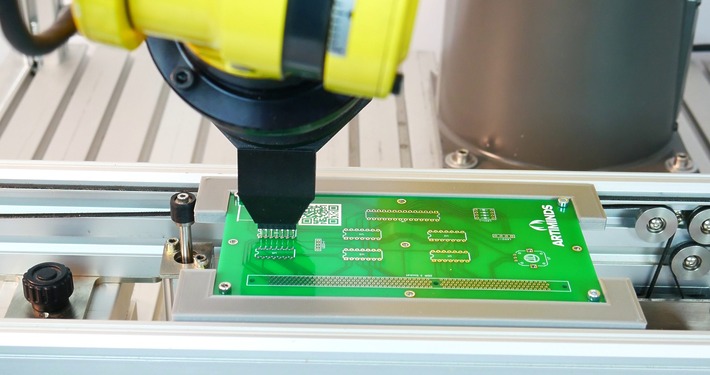

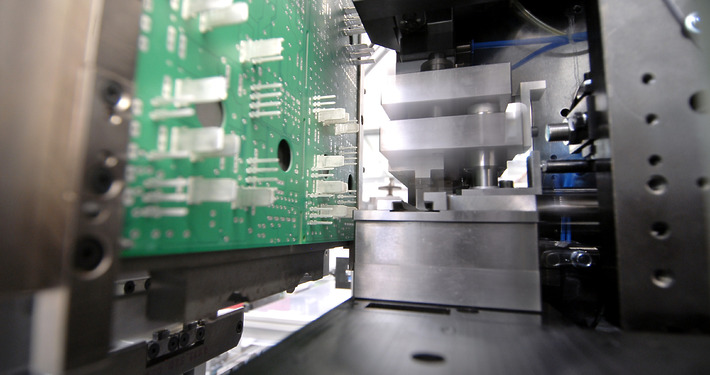

For many components such as transformers, coils, large capacitors or hybrid modules, the THT assembly process often remains a manual task due to its complexity and the precision required. The high sensitivity of these components presents companies with major automation hurdles. The partnership between ArtiMinds and Eberhard aims to close this gap and make the advantages of robotics available for demanding THT applications through innovative technologies.

Innovative technologies for the electronics production of the future

ArtiMinds is contributing its robot-based THT assembly experience and the manufacturer-independent ArtiMinds Robot Programming Suite (RPS) software to the partnership. This intuitive software enables robots to safely and precisely assemble even sensitive and multi-variant components by performing force-controlled, sensor-adaptive joining processes. Thanks to existing interfaces to force-torque sensors and camera systems, an automated THT process can be implemented efficiently, robustly and flexibly.

Eberhard AG complements this with its expertise in the design and manufacture of assembly systems for the electronics industry. Together, the two companies offer a complete solution that increases efficiency, reduces the error rate and cuts costs – all from a single source.

Comments on the partnership

“Our partnership with Eberhard AG is a significant step towards transforming electronics manufacturing,” explains Roman Klingl, Vice President Sales at ArtiMinds Robotics. “With our process expertise and robotics software, we are creating highly flexible THT assembly systems that are tailored to the individual needs of our customers.”

Heinz-Georg Geissler, Director Customer Journey & Authorized Representative at Eberhard AG, also sees great potential: “Combining our expertise enables us to offer a turnkey solution that is technologically leading and economically attractive. Our customers benefit from a complete solution that comes from a single source, from the system through to process development and programming.”

We answer the most important questions about the ArtiMinds software solutions, applications and the company in our FAQ section.

In order to maintain high repeatability and process stability even for large quantities, Primus Präzisionstechnik automated the assembly of a gear unit using a flexible robot cell. The vision- and force-controlled application was programmed with ArtiMinds RPS.

With this white paper, we want to provide you with guidance for your automation plans. To help you to avoid typical pitfalls when using robots, we highlight the top 5 underestimated challenges and stumbling blocks when getting started in robotics and provide you with helpful tips and interactive checklists.