ROBOTICS NEWS

Seamless interlock of online and offline programming

RETHINK ROBOT PROGRAMMING

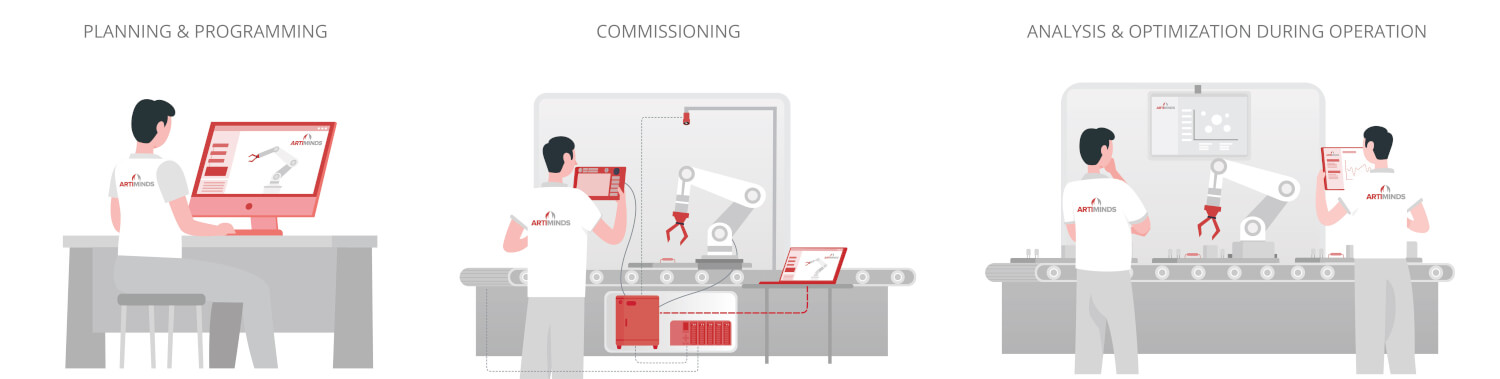

Complex robot applications generally pass through three phases in their life cycle: Planning, programming and maintenance. It is common for problems to occur at the interfaces between the individual phases. On the one hand because different people are responsible during the respective phase, on the other hand because different tools are used. A programming solution that covers all three phases and bridges the gap between the different areas of activity brings numerous advantages. Especially when users can easily switch between online and offline programming. We will explain why.

Offline programming refers to the programming of a robot in a simulation environment, whereas online programming allows programming or testing directly on the real robot. Typically, robot automation projects consist of three steps, involving dedicated online or offline work: Planning, programming and optimization during maintenance. Each phase requires special tools, individual expertise and good coordination, since mostly different people (roles) are responsible for the respective areas.

STATE OF THE ART TECHNOLOGY

At the beginning, the programming and testing cannot yet be done on the real robot. The planner therefore is dependent on simulation tools to determine and validate the geometric design of the robot cell, the tools and the program sequences. He carries out reachability analysis and collision checks, optimizes the sequence of robot actions, determines the most efficient trajectories and defines safety areas.

In the next phase, the programmer faces the difficult task of converting the result – often only available in the abstract form of CAD data, images and process descriptions – into a complex robot program as well as correcting missing or incorrect assumptions. In order to implement the planned process in reality, to calculate robot movements flexibly, to communicate with the PLC, to control tools and image processing systems or to integrate complex sensors such as force-torque sensors, the programmer has to write vendor-specific robot code. If different vendors are used, this inevitably leads to increased efforts.

As soon as the application is running in production, the maintenance team is expected to be able to quickly correct (“online”) and improve not just one but several complex robot programs for different robot manufacturers. In addition, changes need to be documented in a traceable and understandable manner due to shift operation. The programmer needs to prepare the complex robot program in the best possible way in the form of documentation, comments as well as input masks so that the process knowledge represented by the robot code is maintained as good as possible.

A NEW APPROACH

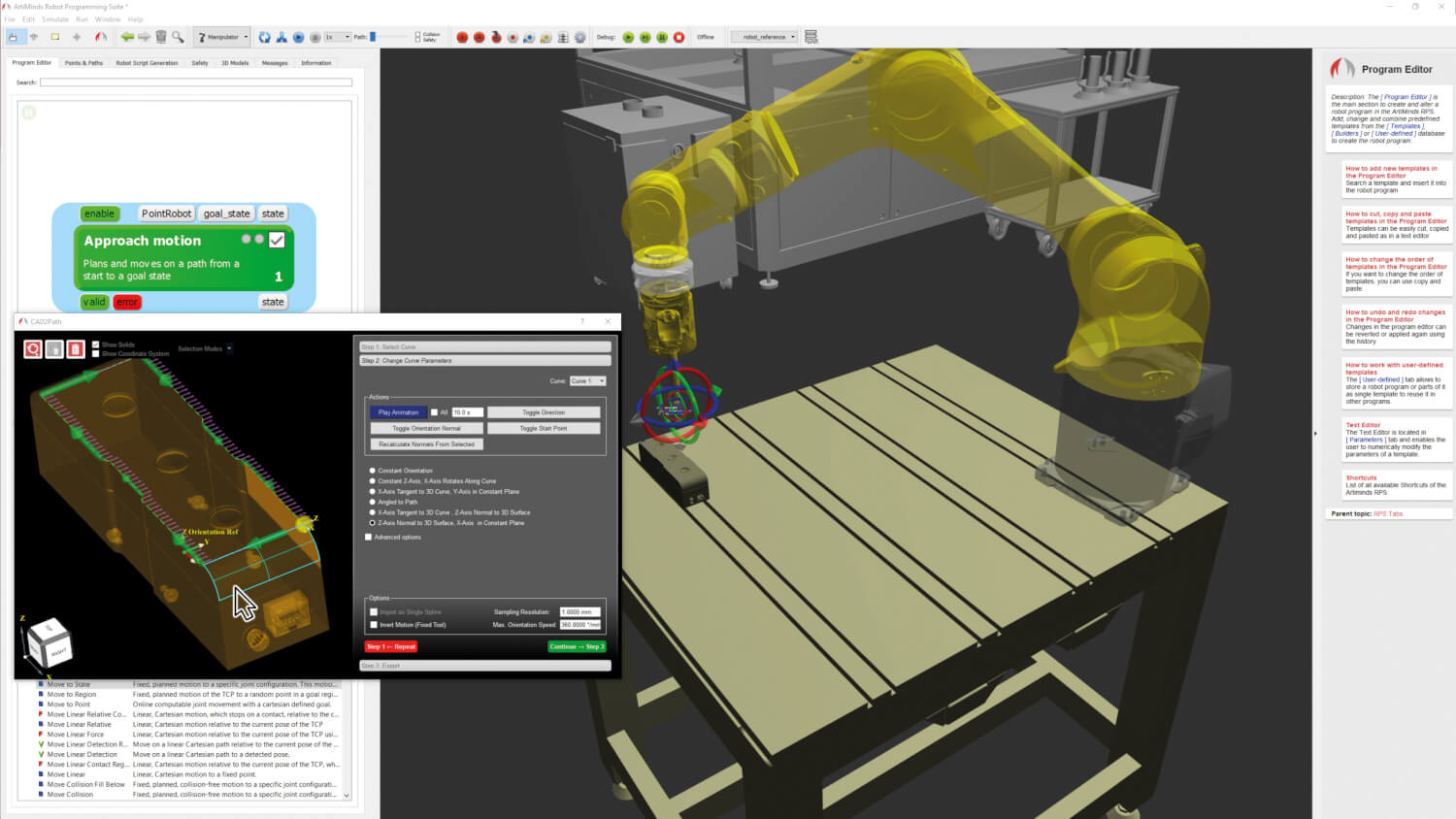

At ArtiMinds we are well aware of the problems associated with these three development phases. Therefore, we have developed the software ArtiMinds Robot Programming Suite (RPS), a new, fully integrated approach that seamlessly combines online and offline programming (Picture 1). Now, the use of only one product suffices for all phases of robot-based automation (Picture 2).

The beauty of the approach is that it is easy to integrate into existing processes, since the software automatically generates robot code that runs on the robot manufacturer’s standard controller. This eliminates the interface problems between different tools. In addition, functional rolls can merge. This allows a more flexible use of resources and increases the efficiency of the cooperation between the individual areas. In the planning phase, for example, more realistic results are produced with the same effort as before, and the robot programmer can then implement them with much less effort. The risk of critical problems occurring in the programming phase only or during commissioning is significantly reduced. Thanks to data consistency and a separate application catalogue, it is also easy to develop standards that apply to all robots.

“What is unusual about our concept is that it allows us to realize not only special partial solutions, but also complex robot automation projects in their entirety. And this with robots from all well-known manufacturers,” explains Dr.-Ing. Andreas Hermann (Picture 3), Senior Team Leader Advanced Robotics at ArtiMinds.

Let´s start and see our software live! Book a free online demo

WHAT TO EXPECT AND HOW LONG WILL IT TAKE?

Invest just 30 minutes of your time and we show you how you can program, analyze and optimize your robot applications with ArtiMinds RPS and ArtiMinds LAR easier, faster, more intuitive and consistent.

The non-binding web demo is the perfect way to find out if ArtiMinds RPS and LAR suit your needs and how the tools can support you .

RAPID TESTING OF DIFFERENT SOLUTIONS

Due to the simplicity of switching between online and offline, the software brings further advantages, which positively affect programming amongst others. For example, when deburring components or inspecting edges, robots often have to run complex trajectories. Programming these trajectories in a motion-oriented manner and comparing them with the real work piece is anything but trivial. This is where ArtiMinds takes a different approach with its RPS. With the tool CAD2Path, CAD models of work pieces can be imported into the offline world and can then directly be used to automatically generate motion paths. For comparison with the real world, the programmer then switches to online mode, moves the robot arm to a set of characteristic points on the work piece and teaches them. Positions from the digital twin can be transferred to the real robot or the other way around (Picture 4). Complex paths can thus be programmed within a very short time. Even transfer movements where accuracy is not important can often be defined more easily offline and, if necessary, their exact target position can be adapted online.

The ability to easily switch between the two worlds means that different solutions can be quickly evaluated directly on the robot, since teaching, programming and testing are closely linked. This is of immense advantage, especially for more challenging applications that have to be tested more often due to the complexity of the programming. One example are sensor-based applications with force-torque sensors or camera systems, which require much more programming effort and expertise than simple movements. Hermann explains, “Programmers can virtually ´abstract the technology away` and concentrate purely on the processes. This also makes the RPS the ideal tool for rapid prototyping of sensor-based assembly tasks. The development cycles of programming, re-teaching, code generation and testing become shorter and different solution strategies can be evaluated efficiently.”

In addition, the use of electric grippers, image processing solutions or force-torque sensors is significantly simplified and the user remains flexible during the setup phase. Even for components offering only simple functions, the initial effort for their integration is usually immense, as numerous protocols have to be implemented and drivers have to be created. Here, the programming suite provides support with a comprehensive range of protocols eliminating this integration effort.

ADVANTAGES FOR MAINTENANCE

Finally, the seamless combination of online and offline programming is also advantageous for maintenance as the RPS facilitates the exchange with the programmers. Hermann adds, “The aim of our current developments is to continuously expand the ´disconnected` mode, i.e. even without RPS, the maintenance engineer can make specific changes in the generated robot code using the robot manufacturer’s standard techniques, such as re-teaching a waypoint.” For example, the maintenance technician can now improve individual teach points with little effort by touch-ups and then feed the updates back into the software. This is very important, because otherwise, documentation and reality would no longer match and essential changes would be lost when implementing additional systems.

With the complementary software LAR (Learning & Analytics for Robots) it is also possible to analyze robot data from real operation. This allows production cycles to be optimized in terms of stability, accuracy and speed. At the same time, LAR makes it possible to compare different program versions with each other. In this way, changes remain transparent and it can be determined reliably whether, for example, an “optimization” is really better than the current program version. In addition, the maintenance engineer benefits from PDF documentation including stored comments that the programmer can create at the touch of a single button.

NO MORE ONE-WAY STREETS

The programming suite is interesting not only for newcomers. It also offers various solutions for companies that already have a library of robot code and want to continue using it. On the one hand, code from previous applications can be integrated and reused for future projects. On the other hand, the opposite approach is imaginable, i.e. that for complex sensor-based sub-processes, for example, code is generated with the ArtiMinds RPS and integrated into the robot’s programming environment.

In general, it has always been important to the robot experts of pur team that they do not dictate users how to use the code and that a step-by-step transition is possible. Hermann sums up, “The combined approach of online and offline programming in combination with the existing control algorithms and the driver library allow to work process-oriented and prevent the loss of focus due to time-consuming detail implementations.”

How did VISOMAX solve the polishing of painted surfaces with robots? Find out more!

MUCH MORE THAN JUST SIMPLE ROBOT PROGRAMMING: With RPS you create cross-process standardization – from planning and programming to maintenance.

Program and simulate robot applications independent of manufacturers, reduce maintenance costs and alleviate the lack of skilled workforces. Find out how ZF succeeds thanks to ArtiMinds!