ROBOTICS NEWS

Structured real time analysis of processes

DIGITAL TWIN FOR ROBOT APPLICATIONS

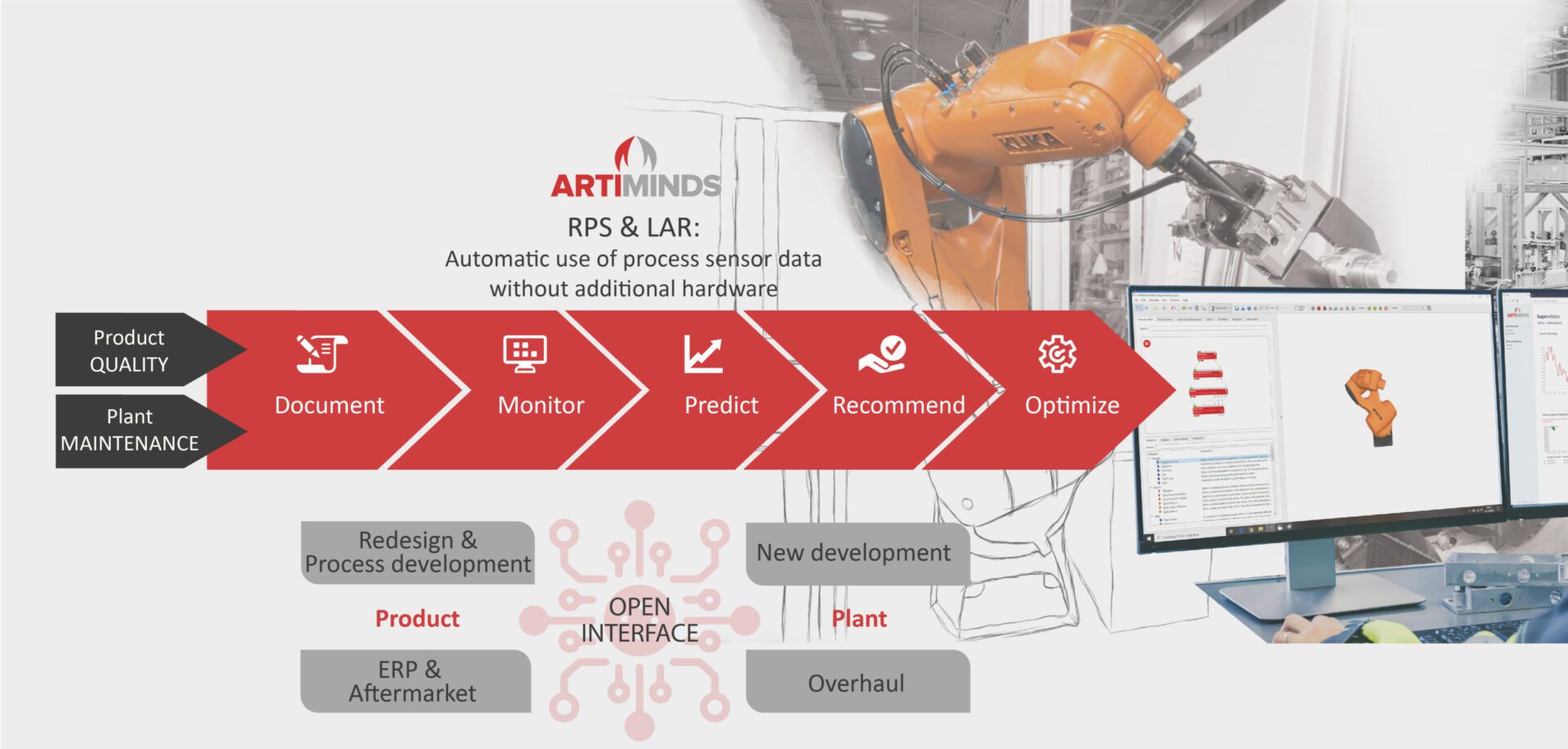

Images in our minds are inspired by words. A wonderful example of this is the evocative term “digital twin“. However, it is also an example of the fact that the ideas that arise in different minds are often not congruent. For example, one important aspect of the digital twin may not be obvious to everyone on the surface. According to the “Gesellschaft für Informatik”, digital twins are more than just data. They consist of models of the objects or processes they represent. In addition, they can also contain simulations, algorithms and services that describe and influence properties or behavior of the respective object or process. They often also offer complementary services. The digital twin is thus usually significantly “smarter” than the plant or process it represents.

In many cases, digital twins collect data from a process, enrich it with information and derive consequences for future action from it, for example through calculations. Used correctly, this results in numerous advantages for process optimization and improvement of product quality. But how does the digital twin obtain the necessary data with relatively little effort? And how is it possible to extract the really relevant data from the abundance of data and to process it in a meaningful way?

ROBOTS AS THE HEART AND HEAD OF A PLANT SECTION

Depending on the solution approach, a digital twin can only be achieved by integrating further hardware or software into the system to be mapped. In robotics applications, however, there is a relatively simple way to realize a digital twin. Dr. Sven Schmidt-Rohr, Chief Executive Officer of ArtiMinds Robotics GmbH, explains: “From our point of view, a digital twin only makes sense if it can be easily integrated into the existing process. We therefore refer to our solution as the intelligent adapter for the digital twin, because it can be used to create a digital twin very quickly and without the use of additional hardware. To do this, we use the robot, which is by nature the central element of a plant section. It is linked to sensors and actuators and communicates with these components anyway.” In other words, a great deal of relevant process data is already available in the robot. If you start here with a solution for data collection, it can be integrated compactly and used easily (Fig. 1). The result is a lean solution that can be integrated into an existing process with little effort. The robotics experts at ArtiMinds demonstrate what this can look like with their Robot Programming Suite (RPS).

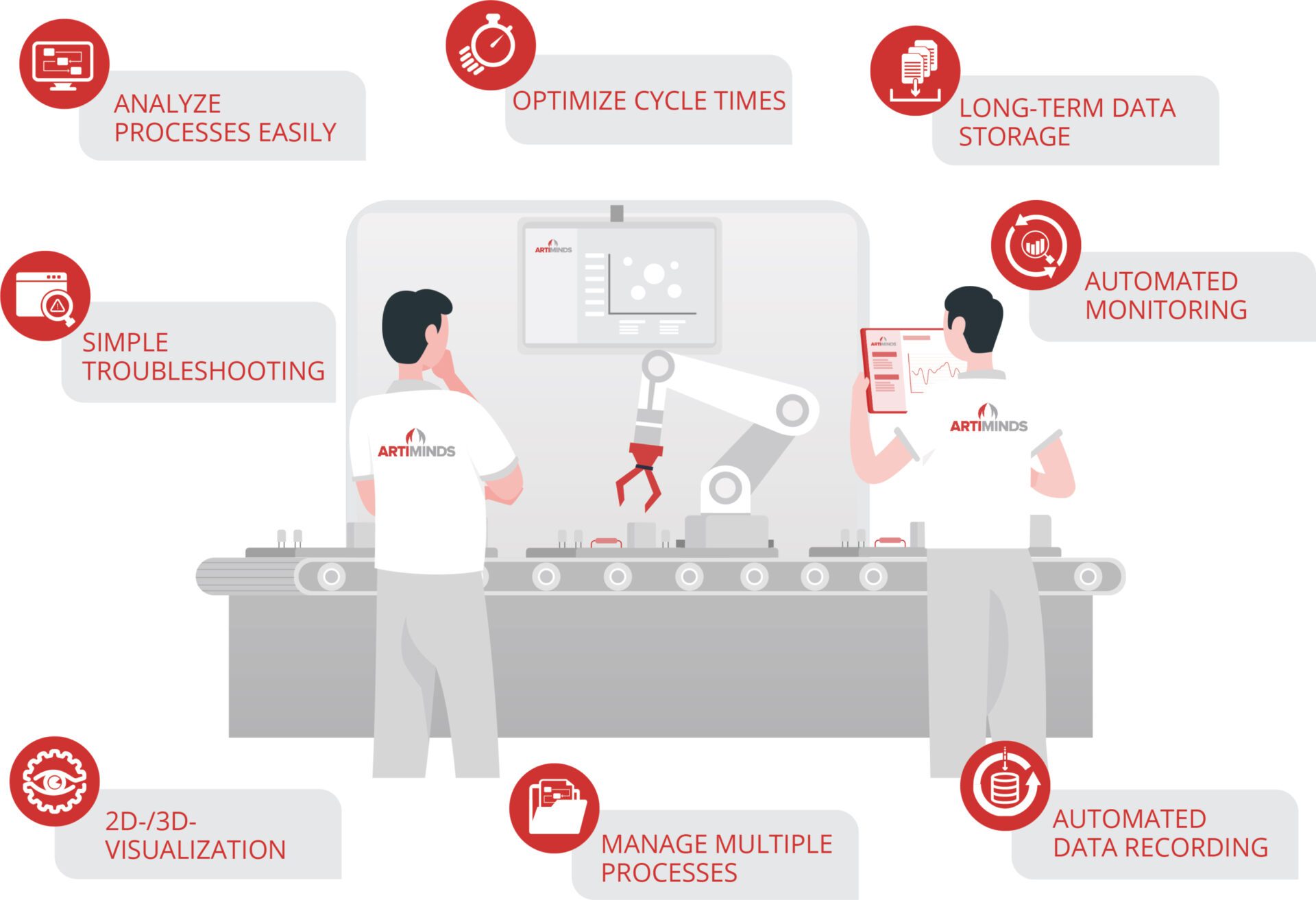

CREATE COMPLEX PROGRAMS AND ANALYSIS VIA DRAG AND DROP

With RPS, robotic applications can be planned, programmed, operated, analyzed and optimized in a single tool. The highlight: The no-code programming approach is manufacturer-independent and is done via drag and drop using individual function blocks. The software then generates the native robot code automatically. Despite the easy-to-use approach, very complex programs can be realized. However, the Programming Suite follows this approach not only in programming, but also in analysis. With the Learning & Analytics for Robots (LAR) add-on module, live sensor data can be monitored, analyzed and optimized. The analyses are also adapted to the respective application with just a few clicks and via the corresponding parameters. LAR can therefore be used to create the digital twin as early as the development stage. It then provides detailed insights into the robotic production process. Based on the Robot Programming Suite, live sensor data from the robot, force/torque sensor, vision system and end effector (that is, the last element of the kinematic chain, for example the gripper or welding head) are transferred from the robot controller. The sensor data is automatically decomposed, assigned to the individual components and permanently stored in a local database at the user’s site.

To create the intelligent adapter for the digital twin, the robot programmer navigates through the various sensor data of the robot program based on the individual function blocks. Schmidt-Rohr explains: “Each function block is used to perform certain tasks. Our LAR tool now automatically makes suggestions for suitable analysis and monitoring options depending on the individual blocks. Here, too, the user then selects from predefined “tiles”, that means analysis methods, or “rules”, the monitoring methods that might be of interest for the sensor data in question (see “Tiles and Rules” technical box). With this approach setup time is drastically reduced. Moreover, even users without in-depth expert knowledge can understand complex processes.”

Dashboards can be set up to visualize the process data (see Fig. 2 below). These can bundle information from different processes or display very detailed analyses for specific sub-processes. Schmidt-Rohr again: “What is displayed in the dashboards can be configured very flexibly. This means that every user can choose the solution that best suits his or her requirements. Processes can be visualized in 2D or 3D. We have a large selection of standard tiles for this as well.” For analyzing force curves along a robot path, for example, it is recommended to display them in 3D diagrams, while 2D diagrams are more suitable for evaluating process tolerances. In the end, the range of information that can be displayed is only limited by the user’s imagination; it ranges, for example, from success rates per component to force-path diagrams of different assembly steps.

TECHNIQUE BOX: TILES AND RULES

By tiles, the robotics experts mean configurable views of raw or processed robot motion data. Users can select from different types of tiles, for example to see plots of force curves or joint angle movements. Statistically processed views of selected blocks over time or their success rates can also be displayed. Tiles can be configured, for example to change the data on the axes (for example, displacement-force plots vs. time-force plots). The underlying data can be flexibly exchanged. This allows users to quickly get an overview of processes and gain new insights.

Rules, on the other hand, automatically check data to determine whether certain properties are met. In doing so, they divide runs into two categories: those that conform to the conditions and those that violate them. For example, users can define thresholds for process parameters, such as the maximum and minimum force during a joining operation. If the force moves outside the allowable range, the violation is detected and the user can verify and evaluate the deviation. It is also possible to run more complex analyses, such as leaving defined ranges out of envelope curves that are automatically calculated from existing data. Rules can be applied to archive data as well as to current projects in progress.

Let´s start and see our software live! Book a free online demo

WHAT TO EXPECT AND HOW LONG WILL IT TAKE?

Invest just 30 minutes of your time and we show you how you can program, analyze and optimize your robot applications with ArtiMinds RPS and ArtiMinds LAR easier, faster, more intuitive and consistent.

The non-binding web demo is the perfect way to find out if ArtiMinds RPS and LAR suit your needs and how the tools can support you .

QUALITY IMPROVEMENT AND PROCESS OPTIMIZATION

Users benefit in many ways from an intelligent digital twin that is easy to set up. In terms of quality, two topics are becoming increasingly important in automated production: digitally supported plant maintenance and digitally managed product quality. Both are closely interlinked when looked at closely. The intelligent digital twin adapter can help with both. Without additional hardware, it automatically collects and evaluates inline sensor data from the process. In this way, it documents the process behavior in detail for each day and stores the history of the digital twin. This provides insights into the production process that were not easily available before. Plant operators no longer have to rely on the “gut feeling” or the good ear of the plant supervisor with many years of experience, but have clear data and facts that reflect the condition of the plant and the quality of the manufactured products. The detailed documentation of the entire process behavior for each cycle is a very helpful tool for process optimization and quality improvement. Especially in the case of sporadically occurring errors, it is often difficult to understand in retrospect what caused them. If process data is recorded, evaluated and consistently stored, it is still possible to investigate the causes and eliminate errors in retrospect.

In addition to historical data, however, the digital twin also shows current process behavior and helps to detect anomalies in real time. Coupled with clever calculations, it can automatically determine which process adjustments are necessary to prevent a plant malfunction or product quality violations. The Start-End Point Analysis tile, for example, automatically calculates suggestions on how the robot program can be modified to optimally compensate for any tolerances that occur in a particular sub-process. This enables the plant operator to react quickly and purposefully during the running process. In addition, predictions can be made with regard to system malfunctions on the one hand and product quality violations on the other. For this purpose, the Epsilon-Tile monitors, for example, in which sub-process the sensor data take an unexpected course.

Schmidt-Rohr sums up: “These tiles are just two examples of analysis and monitoring methods that we make available to users as standard. With these methods, they can create a digital twin with very little effort, which helps them to monitor and specifically further improve their performance and product quality over the entire life phase of a plant.”

How did VISOMAX solve the polishing of painted surfaces with robots? Find out more!

MUCH MORE THAN JUST SIMPLE ROBOT PROGRAMMING: With RPS you create cross-process standardization – from planning and programming to maintenance.

Program and simulate robot applications independent of manufacturers, reduce maintenance costs and alleviate the lack of skilled workforces. Find out how ZF succeeds thanks to ArtiMinds!