ROBOTICS NEWS

ROBOTICS TIP: Changes during the lifecycle of a robot cell

Why operational effects are very time consuming for robot programmers

During the lifecycle of a robotic cell, a system is exposed to numerous operational influences.

These can be shocks and vibrations triggered, for example, by forklifts or other machines, the wear of tools, spare parts that react differently than the previous components, changes in work piece batches or space available in the hall. Changing lighting and temperature conditions or the difference between a cold-started and a warmed-up robot can also have an effect.

What does this mean in concrete terms? Any change in the setting of the system, no matter how small, can affect the process to be executed and lead to errors or deviations. Every time when material expands or contracts due to temperature differences, when the vision system can no longer perform the detection job correctly due to different lighting conditions, or when wear and tear affects the surface texture and shape, adjustments to the robot program are necessary to ensure that the system runs robustly and error-free.

ARTIMINDS LAR – DERIVED ANALYSIS

These adjustments involve programming effort and often the occurring changes are not even directly visible to the naked eye. And when the system no longer runs as originally set up, the troubleshooting begins.

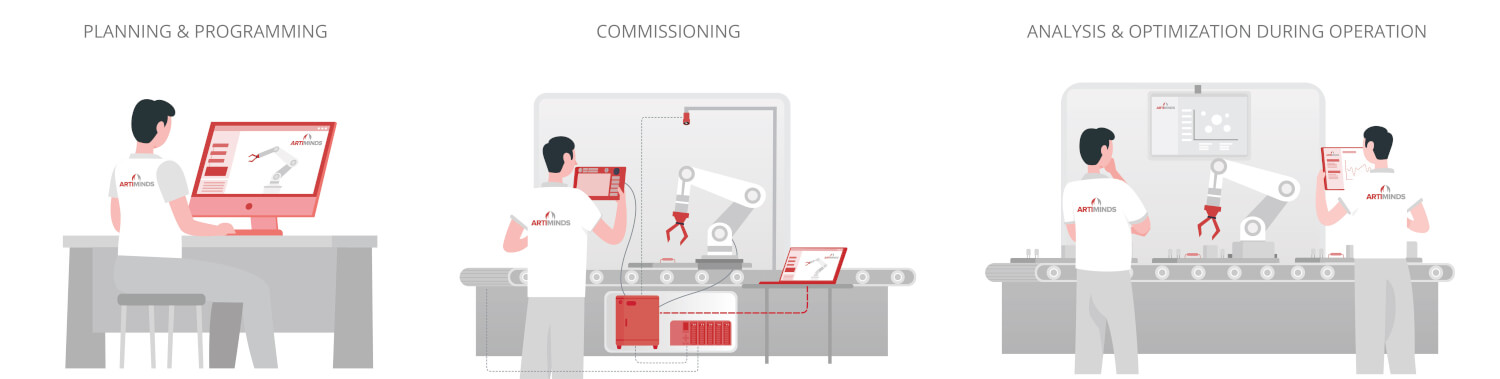

ArtiMinds RPS first of all minimizes the effort involved in making changes due to the template-based programming environment. And in combination with ArtiMinds LAR, deviations, no matter how small, can be detected BEFORE the system goes on strike. The software automatically collects all available sensor data, analyzes it and graphically displays the results. Derived adjustments can now be made specifically for the respective templates in RPS.

CUSTOMER BEST PRACTICE EXAMPLE: PRIMUS PRÄZISIONSTECHNIK

LAR has also helped Primus Präzisionstechnik to make virtually invisible changes visible.

Robot programmer Michael Castien explains, “We have two robots with the same program. The analysis data from the LAR showed that there are still differences, though, and contrary to our assumption, the two systems don’t run the same.”

Using this data, Castien was able to readjust the precision to within 100ths and, after a few runs, re-evaluate whether or not the changes had the desired positive effect.

The company tells more about the use of ArtiMinds at Primus in the corresponding success story.

We answer the most important questions about the ArtiMinds software solutions, applications and the company in our FAQ section.

Program and simulate robot applications independent of manufacturers, reduce maintenance costs and alleviate the lack of skilled workforces. Find out how ZF succeeds thanks to ArtiMinds!

Don’t miss our new webinar series “Automating with robots”. Learn in 5 tips how you can deploy robots quickly, flexibly and future-proof and how you can program them easily and independently of any manufacturer.