ArtiMinds RPS & LAR at a glance

Planning and programming

ArtiMinds RPS provides over 60 program templates (function blocks) with which you can create your robot program modularly via drag & drop. Especially in complex applications including PLCs, sensors, or electric grippers, these predefined and proven sub-processes save a lot of effort and time. Use the integrated configurator to create your individual robot setup easily. The 3D simulation environment makes it possible to check accessibilities and to visualize collisions as early as in the planning phase. The software also supports you with collision-free path planning or the generation of tool paths for complex CAD geometries.

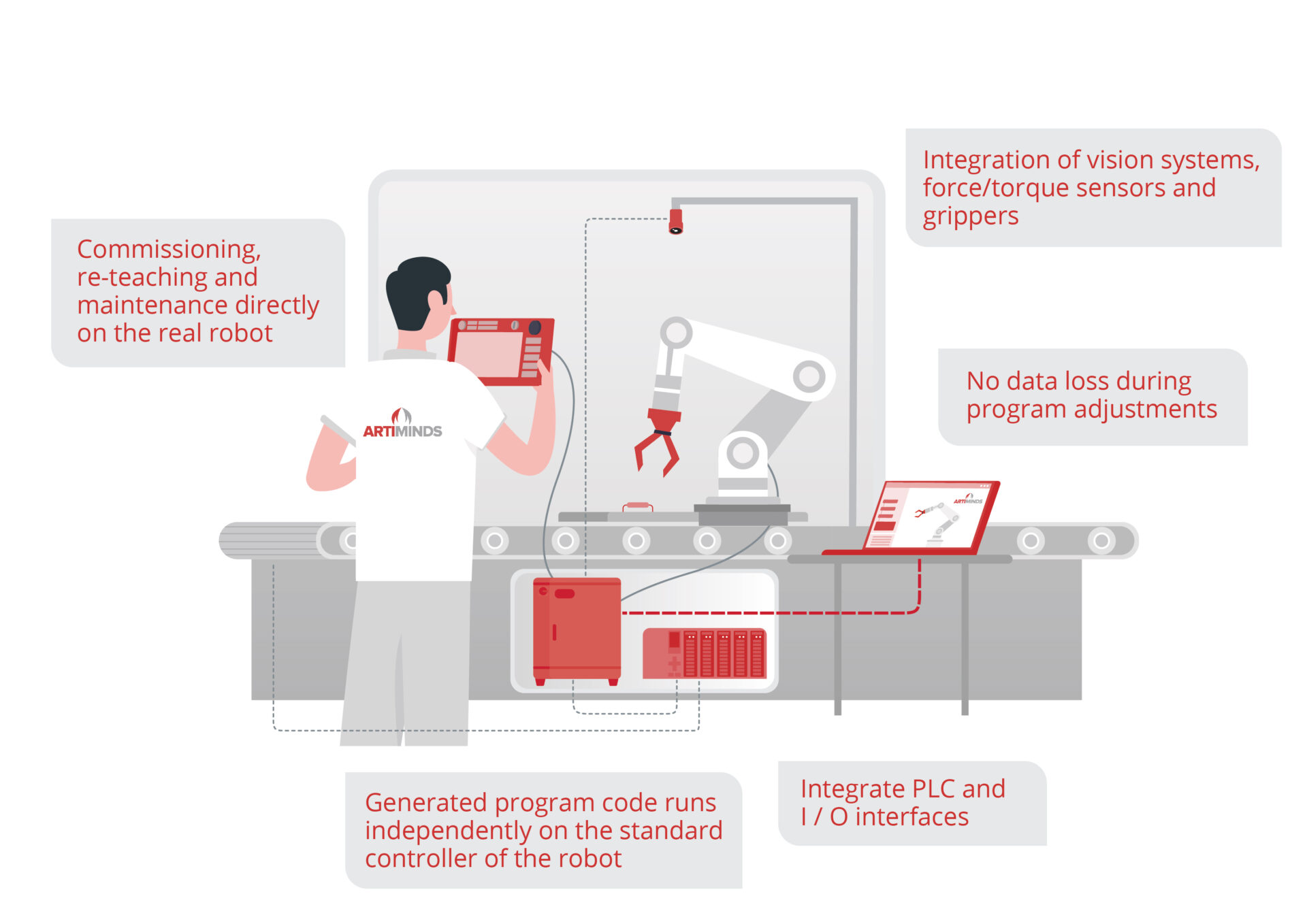

Commissioning

With ArtiMinds RPS, you can generate native program code that runs intependently on the standard robot controller – without having to write a single line of robot code. This enables you to use any functionality of your robot controller at any time. Thanks to the seamless combination of online and offline programming, commissioning, maintenance as well as re-teaching of individual points is possible directly on the real robot. Transfer changes made on the robot controller back into the software or carry out an automatic comparison of the robot code and the RPS program. The broad support of force/torque sensors, vision systems or electric grippers as well as the option to integrate PLC and I / O interfaces ensure both, the smooth integration of ArtiMinds into new and existing automation plants.

That´s what our customers say

ArtiMinds has been a great addition to my robotic programming capabilities. I’ve been able to perform force controlled checks and movements that I would not have ever been able to without the software.

ArtiMinds enables a much faster programming and is backed by its responsive and competent support.

After the first talks and presentations , I knew : This is exactly what we need . The Robot Programming Suite enables us to do universal robot programming at a qualitatively higher level.

Planning, programming and operating robot applications – with ArtiMinds RPS

Watch the video to learn how this works in just three steps thanks to continuous online and offline programming or ask our team for a non-binding individual online demo.

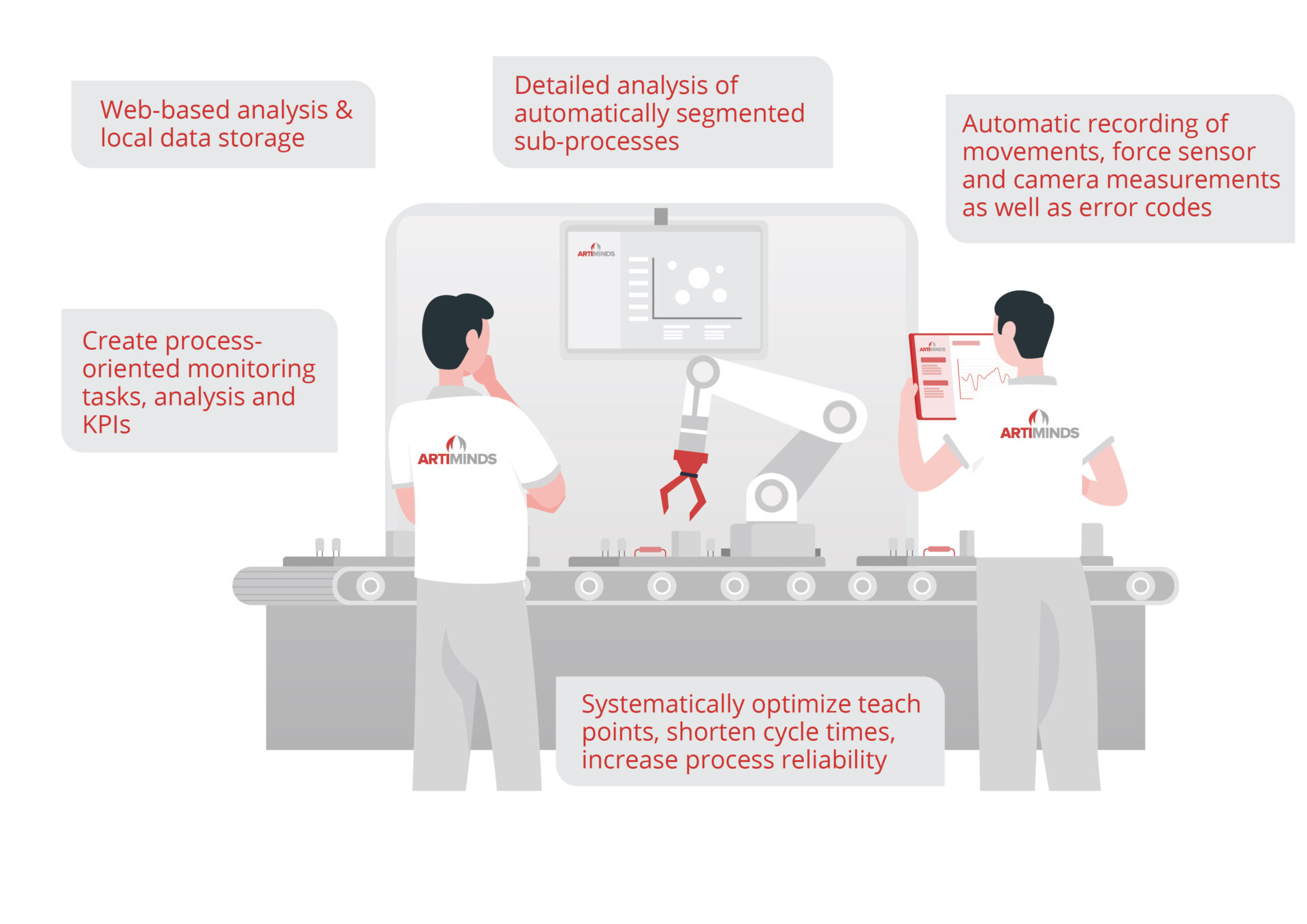

Analysis and optimization during operation

The focused analysis and optimization is the most important step after programming: ArtiMinds LAR automatically records live sensor data such as movements, force/torque sensor and camera measurements or error codes and evaluates them. The data is only stored locally and made available to you via a web application. This ensures you to stay flexible and have mobile access at any time. The division into sub-processes is automated. This allows you to carry out a quick, targeted detailed analysis particularly for your process. The data is processed graphically and numerically, allowing you e.g. optimizing teach points, shortening cycle times and thereby increasing process reliability.

GET STARTED AND LEARN MORE IN A FREE ONLINE DEMO

In just 30 minutes, we will show you how to plan, program, operate, analyze and optimize robot applications cost-efficiently, intuitively and easily with ArtiMinds RPS.

The non-binding free online demo is the perfect way to get a first impression of the software, the application portfolio and if it suits your needs.

Program and simulate robot applications independent of manufacturers, reduce maintenance costs and alleviate the lack of skilled workforces. Find out how ZF succeeds thanks to ArtiMinds!

How did VISOMAX solve the polishing of painted surfaces with robots? Find out more!

We answer the most important questions about the ArtiMinds software solutions, applications and the company in our FAQ section.